CAPABILITIES

Our Advantage

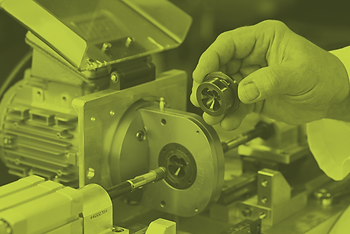

The one-piece construction of our cutters provides greater stability and consistent high-quality manufacturing tolerances. The four blades of our patent-pending four-blade hugger design are evenly spaced at 90 degrees, providing greater mechanical stability, reduced chatter and reduced consumption of the weld cap. The hugger control tabs improve capture and maintain the precise amount of cutter aggressiveness, while the weld face control zone slows the cutting action once full dress is achieved. The result is a controlled cut rate, longer cutter life and reduced chip size.

Highest-Quality Manufacturing

Using certified tool steel, specialized tooling for dimensional quality, and unique coating processes, our cutters and housings are manufactured to meet the highest performance standards for optimum strength and durability.

-

Heat-treated for strength and durability

-

Polishing/deburring for sharp edges

-

Special coating for carbide surface hardness

-

Double coating for additional lubricity, durability and performance

Rigorous Quality Control, Testing and Tracking

Our rigorous quality control processes include precision analyses using micro-level testing standards. All of our products are serialized, date-coded and registered by small lot codes for customer tracking and small-batch quality control. Our heat-treating and coating processes are also analyzed to ensure they meet exacting performance standards.

To learn more about how our innovations in cutter geometry are advancing tip dressing, download our free white paper.